When creating a brochure, selecting the right printing technique is just as important as the design and content. The printing method not only affects the final appearance but also plays a role in costs, durability, and overall impression. From traditional methods to innovative digital solutions, brochure printing techniques vary widely to suit different business needs and creative goals.

1. Offset Printing

Offset printing is one of the most commonly used techniques for high-volume brochure production. It works by transferring ink from a plate to a rubber blanket, then onto the paper surface. This method delivers excellent print quality and precise color accuracy. It is ideal for bulk orders because the cost per unit drops significantly as the quantity increases.

- Pros: High-quality results, cost-effective for large runs

- Cons: Longer setup time, not ideal for short print runs

2. Digital Printing

Digital printing has revolutionized the world of brochure printing with its speed and flexibility. Unlike offset, this method does not require plates. Instead, the artwork goes directly from the computer to the printer. This makes it ideal for small batches and fast turnarounds and allows for easy customization of individual brochures.

- Pros: Fast setup, great for short runs and personalization

- Cons: Slightly lower color consistency compared to offset

3. Flexography

This is a modern form of letterpress printing that uses flexible relief plates. Typically used for packaging and labels, flexography can be applied to brochure projects with unconventional materials or surfaces. It’s particularly effective when printing on non-paper substrates.

- Pros: Versatile for different surfaces, fast rotary printing

- Cons: Not commonly used for standard brochures

4. Screen Printing

Screen printing is a manual method that involves passing ink through a mesh screen onto the material. While time-consuming and not suitable for mass production, it produces bold, vibrant colors and can be used on various materials including fabric and plastic.

- Pros: Rich colors, can print on multiple materials

- Cons: Slow process, not efficient for large quantities

5. Gravure Printing

This high-end printing technique is known for its exceptional image reproduction quality. Gravure printing uses engraved cylinders to apply ink, making it perfect for producing sophisticated brochures with photographic detail. However, its high setup costs often make it suitable only for large-scale, luxury brochure projects.

- Pros: Outstanding image quality, excellent color depth

- Cons: Expensive setup, mainly used for high-end purposes

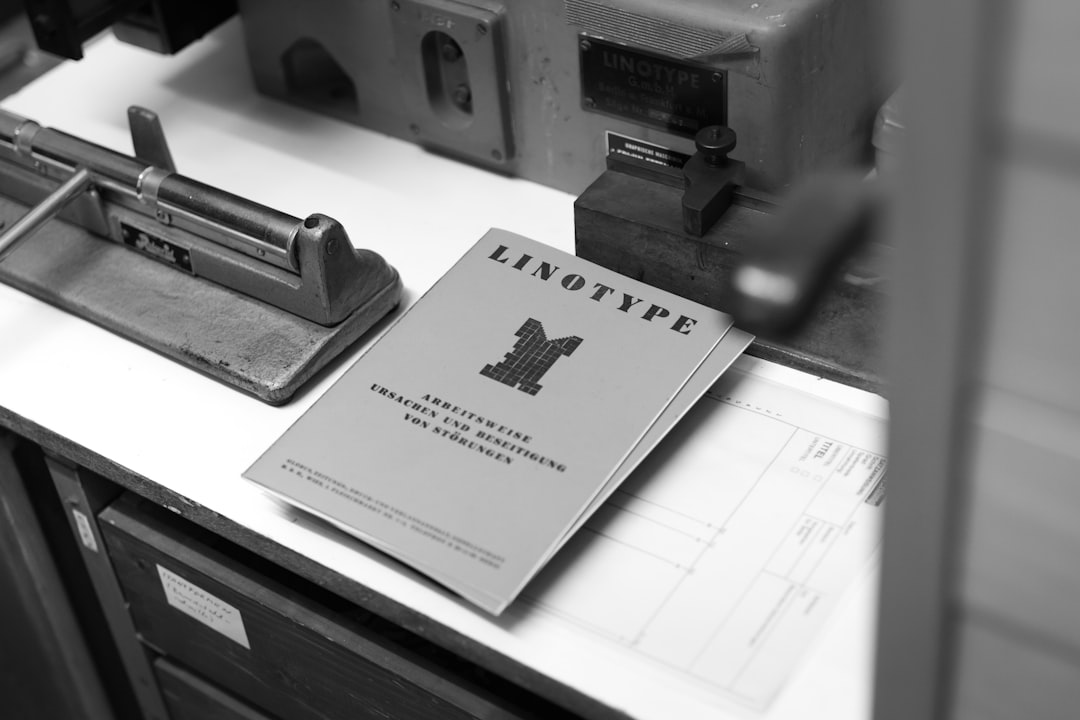

6. Letterpress Printing

Letterpress involves pressing inked plates into paper to create an impression. Although it’s an old technique, its tactile finish and unique aesthetic have made it popular again, especially for artistic or premium brochure designs. Often used for limited edition prints, it adds a handcrafted feel.

- Pros: Unique texture, elegant appearance

- Cons: Costly and time-intensive

Choosing the Right Technique

The choice of printing technique largely depends on the brochure’s purpose, budget, and design complexity. For corporate brochures requiring a polished and professional look, offset or digital printing might be best. For creative or luxury projects, techniques like letterpress or gravure offer distinctive advantages. Understanding the strengths of each method ensures the final product aligns with the intended message and brand image.

FAQs

- Q: Which printing technique offers the best color quality?

A: Gravure printing offers the highest color depth and image quality, though offset printing is also excellent for color accuracy. - Q: What is the most cost-effective method for small print runs?

A: Digital printing is the most economical for short batches and offers quick turnaround times. - Q: Are environmentally friendly printing options available?

A: Yes, both digital and offset printing can use vegetable-based inks and recycled paper to reduce environmental impact. - Q: Can I print brochures on non-paper materials?

A: Flexography and screen printing are ideal for printing on materials like plastic, fabric, or metal surfaces. - Q: Is it possible to customize each brochure in a print job?

A: Absolutely. Digital printing enables variable data printing, allowing for unique content on each brochure in a single print run.