In the vast, complex world of semiconductor manufacturing, the focus often falls on Asian production sites, tech giants, and chip designers. However, one of the most vital components in the creation of high-performance chips depends on a far less known facility nestled in the quiet hills of North Carolina. This quartz factory, almost unknown outside of certain specialized circles, plays a critical role in enabling the multi-trillion-dollar global chip industry to function smoothly.

TLDR (Too Long, Didn’t Read)

Though chips are seen as marvels of engineering, their creation depends on extremely pure quartz components, many of which originate from a single facility in North Carolina. This factory produces fused quartz used in the photolithography process of chipmaking. Without this material, chip production worldwide would grind to a standstill. The security and reliability of this facility make it a linchpin in the intricate chain that fuels modern technology.

Why Quartz Is So Crucial for Chipmaking

To understand the strategic importance of the quartz factory in North Carolina, one must first understand the critical role quartz plays in semiconductor fabrication.

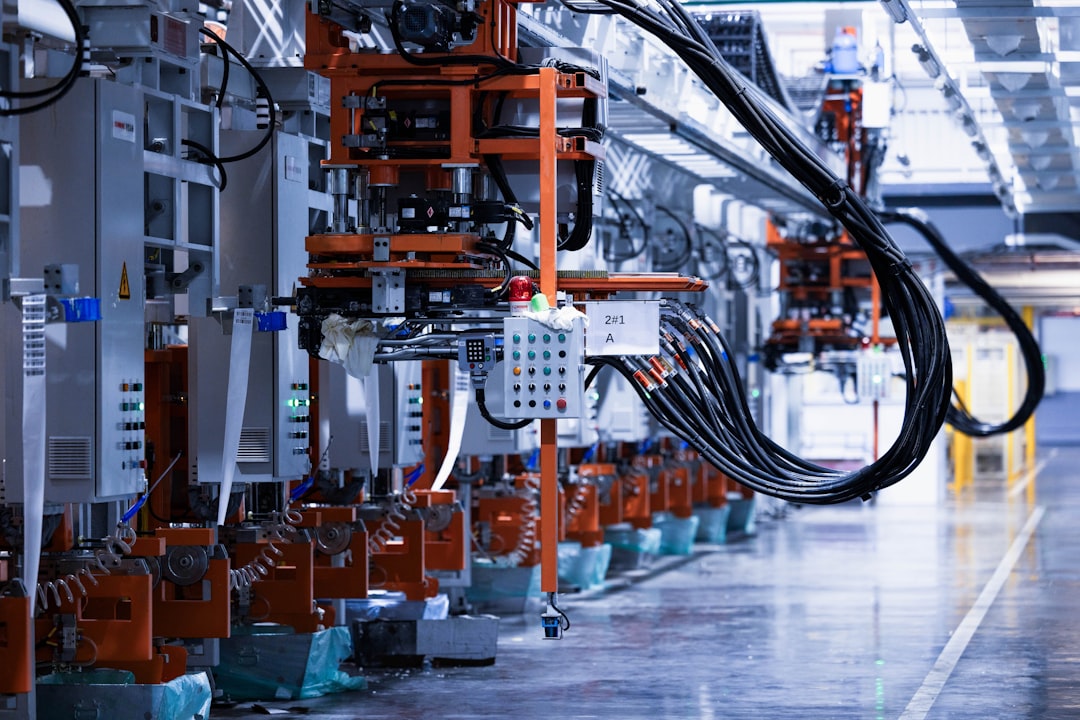

In chip manufacturing, particularly the photolithography process, fused quartz is trusted for its exceptional purity, resistance to high temperatures, and ability to transmit ultraviolet light without distortion. Photolithography is the technique used to project circuit patterns onto silicon wafers, and it requires flawless optical components to maintain precision at the nanometer scale.

Most of these optical components—including lenses, tubes, and crucibles—are made from fused quartz. But the level of purity required exceeds 99.9999%, a grade known as “six nines” or 6N purity. This is where the North Carolina factory comes into play, as one of the very few places on earth capable of reliably producing quartz at this unrelenting standard.

A Small Factory With a Global Reach

The facility—quietly located in Spruce Pine, North Carolina—is operated by a company known among industry insiders but far from a household name. Its specialty is mining and refining the purest natural quartz in the world, a feat that not only requires geological resources but also decades of accumulated know-how.

The pegmatite found in the Appalachian Mountains surrounding Spruce Pine is uniquely suited for this kind of extraction. Nowhere else on Earth does quartz occur with such low levels of unwanted metallic impurities. From this raw quartz, the factory fabricates components that are then shipped to chip foundries and equipment makers across the globe.

This quartz factory supports companies such as ASML, the Dutch company that builds the world’s only extreme ultraviolet (EUV) lithography machines, and others dependent on photomask substrates and optics engineered with wafer-thin tolerances. In simple terms, remove this factory from the equation, and the chipmaking process itself begins to falter.

Why There Are So Few Alternatives

It might seem surprising that such a vital piece of global infrastructure is so geographically concentrated. But this fragility is a result of both geology and geopolitics. Here’s why alternatives are so limited:

- Geological Rarity: Quartz of sufficient purity occurs in only a handful of locations globally, and even fewer can be refined to meet semiconductor-grade standards.

- Technology and Expertise: The purification and handling technologies developed over decades at the North Carolina site are proprietary and extremely complex.

- Economic Risk: Building a duplicate facility elsewhere would require substantial investment with uncertain returns, given the existing supply’s proven reliability.

This has put an outsized level of strategic importance on the Spruce Pine factory. Tech companies worldwide are aware of this dependency but have found no viable “Plan B.” In fact, during global supply disruptions, including those caused by the COVID-19 pandemic and geopolitical tension, the factory became a behind-the-scenes focus of major industry players trying to secure materials for uninterrupted production.

Photolithography and The Quartz Connection

Perhaps the clearest way to understand the dependence on this raw material is by looking at how chips are actually patterned at the nanoscale. In EUV photolithography—which enables features as small as 7 nanometers or less—extremely short-wavelength light shines through photomasks onto photoresist-covered wafers. Any loss of transmission clarity can ruin a batch of extremely valuable chips.

To prevent this, every optical surface involved in these machines must be made of ultra-pure quartz. The slightest impurity causes scattering or absorption of light, which ruins the precision that chipmakers strive for. And since such lithography machines cost more than $150 million apiece, there’s no tolerance for error or experimentation. That’s why companies prefer to stick with trusted quartz sources—namely, the one in North Carolina.

The link between fused quartz and photolithographic precision cannot be overstated—in fact, it’s fair to say that without Spruce Pine quartz, advanced chips simply wouldn’t exist.

Strategic Implications and National Security

The United States government has increasingly come to view the quartz industry through a national security lens. In an era of rising tensions with China, the U.S. has prioritized stabilizing domestic semiconductor supply chains—including ensuring secure access to the materials that make manufacturing possible.

Thus far, the quartz factory has remained reliable. But its strategic importance has prompted discussions within the Pentagon and various industrial policy centers about enhancing protections, redundancy, and contingency planning for this piece of infrastructure. Stateside production of chips might mean little if access to a single raw material becomes compromised.

It would not be an exaggeration to say that the future of computing, modern telecommunications, and even military hardware (many of which are reliant on advanced chips) is tied in some measure to the uninterrupted function of this quartz factory in North Carolina.

A Quiet Cornerstone of the Digital Age

While public attention focuses on chip shortages, mega-fabs in Taiwan and Arizona, and new advances in processor architecture, few recognize the quiet and essential role of quartz manufacturing. Yet without it, the spectacular progress in miniaturization and performance that defines the modern tech landscape would stall.

In looking at the future of semiconductors—which includes AI acceleration, quantum computing, 3D chip stacking, and more—it’s worth remembering the old adage: you can’t build a brilliant tower without a solid foundation. In many ways, North Carolina quartz is that foundation.

Conclusion

As technology continues to advance at breakneck speed, dependencies in the supply chain grow more complex and more precarious. The quartz factory in North Carolina, while far from the spotlight, illustrates just how intricately every layer of chipmaking is interwoven. From a single factory tucked away in Appalachia comes the material that underpins an entire sector of transformative global technology.

Organizations and governments are beginning to understand what industry insiders have known for years: if you want to secure the future of computing, you must start with the rock—quite literally—upon which it’s built.